|

|

|

One of the first questions a pilot might ask, when converting to a new aircraft type is: "What's the stall speed?" The reason for the enquiry is that usually, but not always, the approach speed chosen for landing is about 1.3 times the stall speed. Stall is often an undesirable phenomenon (except for aerobatic purposes) when the aircraft wings produce an increased air resistance (drag) and decreased lift that may cause the aircraft to crash. The stall occurs when the airflow separates from the upper wing surface. It happens when a plane is under too great an Angle of Attack (AoA). For light aircraft, without high-lift devices, the critical angle is usually around 16o. The picture below shows a stalled airfoil:

Geometric Angle of Attack is the angle between the airfoil chord line and the direction of flight. The Angle of Attack is also known as Alpha. The angle of attack measured relative to zero coefficient of lift is called the Absolute Angle of Attack (Absolute AoA). There's also the Pitch Angle, which is measured with respect to the horizon. For symmetric airfoils the Absolute AoA is equal to the Geometric AoA, whereas for asymmetric (cambered) airfoils these two angles are different, since these airfoils still produce lift at zero Geometric Angle of Attack as shown below.

For airfoils of one family the symmetric airfoil stalls at a higher Geometric AoA compared with the cambered airfoil, however the cambered airfoil has higher lift coefficient and stalls at a higher Absolute AoA. As mentioned in the chapter Forces in Flight, the lift force is proportional to the density of the air r, the square of the airspeed V, the type of airfoil and to the wing's area according to the formula: Lift force = 0.5 * r * V2 * wing's lift coefficient * wing area Since lift coefficient is proportional to the angle of attack, the lower the airspeed, the higher the angle of attack has to be in order to produce the same lift. Thus, stall may occur during take-off or landing, just when the airspeed is low: To keep altitude at low airspeed, the wing's lift coefficient has to increase, and if a non-experienced pilot tries to lift the aircraft's nose at a too low airspeed, it may exceed the critical angle of attack and stall occurs. If you're flying near the stall speed and make a steep turn, the aircraft will stall. That's because, if the aircraft stalls for instance at 20 knots in straight level flight, it will stall at 28.2 knots in a 60 degree banked turn. The rapid reduction in speed after passing the critical angle of attack means the wing is now unable to provide sufficient lift to totally balance weight and, in a normal stall, the aircraft starts to sink, but if one wing stalls before the other, that wing will drop, the plane falls out of the air. The ground waits below. Stalls may also occur at high airspeeds. If at max airspeed and full throttle the pilot suddenly applies excessive up elevator, the aircraft will rotate upwards, however, due to aircraft's inertia, it may continue flying in the same direction but with the wings at an angle of attack that may exceed the stall angle. See an example here Stalling at high-speed gives a more dramatic effect than at low speed. This because the strong propeller wash causes one of the wings to stall first that combined with the high speed produces a snaproll followed by a spiral dive. This happens very fast causing the aircraft to dive at full throttle and unless there's enough height for recovery, the crash will be inevitable. An aircraft with relatively low wing loading has a lower stall speed. (wing loading is the aircraft's weight divided by the wing area) Since the airfoil also affects the max angle of attack and so the stall speed, many aircraft are equipped with Flaps on the wing's trailing edge, and some designs use Slats, which opens up a Slot between the wing's leading edge and the Slats. Flaps increase the wing's lift coefficient, but the simple ones may reduce the stall angle. Slats, on the other hand, increase the stall angle. Aircraft that are designed for Short Take-Off and Landing (STOL) often use fixed Slats on the wing's leading edge together with Flaps on the trailing edge, which gives high lift coefficient and remarkable slow flying capabilities by allowing greater angle of attack without stalling.

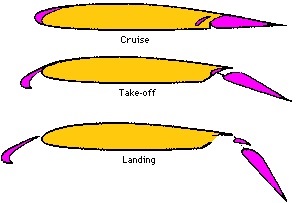

Cruise TakeoffThe leading edge Slats may prevent the stall up to approximately 30o AoA by picking up a lot of air from below, accelerating the air in the funnel shaped Slot (venturieffect) and forcing the air around the leading edge onto the upper wing surface:

The disadvantage of the Slats, Slots and Flaps is that they produce high drag. But since the high lift coefficient is only needed when flying slowly (take-off, initial climb, final approach and landing) some designs use retractable devices, which retract at higher airspeeds to reduce the drag.

Such devices are seldom used in model aircraft (especially the smaller ones), mainly due to its complexity and also the increasing of wing loading, which may counter-act the increased lift obtained. The wing's aspect ratio (AR) also affects the overall lif coefficient of the wing. For a given Re, the wing with higher AR (with long wingspan and small chord) reaches higher lift coefficient, but stalls at a lower angle of attack than the wing with low AR as shown below:

However, for a given wing area, increasing the aspect ratio may result in a too small wing chord with a too low Re number, which may significantly reduce the lift coefficient. This is likely to occur with small indoor planes. Another method to improve an aircraft's stall characteristics is by using wing washout, which refers to wings designed so that the outboard sections have a lower angle of attack than the inboard sections in all flight conditions.

The outboard sections (toward the wing tips) will reach the stalling angle after the inboard sections, thus allowing effective aileron control as the stall progresses. This is usually achieved by building a twist into the wing structure or by using a different airfoil in the outboard section. A similar effect is achieved by the use of flaps. The aileron drag is a further factor that may cause an aircraft to stall. When the pilot applies aileron to roll upright during low speed, the downward movement of the aileron on the lower wing might take an angle on that part of the wing past the critical stall angle. Thus that section of wing, rather than increasing lift and making the wing rise, will stall, lose lift and the aircraft instead of straightening up, will roll into a steeper bank and descend quickly. Also the wing with the down aileron often produces a larger drag, which may create a yaw motion in the opposite direction of the roll. This yaw motion partially counteracts the desired roll motion and is called the adverse yaw. Following configurations are often used to reduce aileron drag: - Differential ailerons where the down-going aileron moves through a smaller angle than the up-going. - Frise ailerons, where the leading edge of the up-going aileron protrudes below the wing's under surface, increasing the drag on the down-going wing. - And the wing washout. Stall due to aileron drag is more likely to occur with flat bottom wings. Since differential ailerons will have the opposite effect when flying inverted, some aircraft with symmetrical airfoils designed for aerobatics don't use this system. The picture below illustrates an example of a Frise aileron combined with differential up/down movement.

Another factor that affects the aircraft's stall characteristics is the location of its centre of gravity CG. A tail-heavy aircraft is likely to be more unstable and susceptible to stall at low speed, e. g. during the landing approach. Downwind stall: For instance, a powered plane flying north with airspeed of 30 knots against a 30 knots headwind has zero ground speed. If you turn 90 deg. left (west), the plane's airspeed still is 30 knots but is now drifting 30 knots to the south resulting in 42 knots ground speed to the southwest. If the plane keeps turning south, the drift due to the wind is still 30 knots but now the ground speed becomes 30+30 = 60 knots, while the airspeed still is 30 knots. The pilot on the ground will see the ground speed but not the airspeed, and since the plane seems to move much faster flying downwind, the pilot may instinctively slow down the plane below the stall speed. This results in a pilot-induced stall due to the optical illusion of the plane's higher ground speed when flying downwind. Recovering from a stall: In order to recover from a stall, the pilot has to reduce the angle of attack back to a low value. Despite the aircraft is already falling toward the ground, the pilot has to push the stick forward to get the nose even further down. This reduces the angle of attack and the drag, which increases the speed. After the aircraft gained speed and the airflow incidence on the wing becomes favourable, the pilot may pull back on his stick to increase the angle of attack again (within allowable range) restoring the lift. Since recovering from a stall involves some loss of height, the stall is most dangerous at low altitudes. Engine power can help reduce the loss of height, by increasing the velocity more quickly and also by helping to reattach the flow over the wing. How difficult it is to recover from a stall depends on the plane. Some full-size aircraft that are difficult to recover have stick shakers: the shaking stick alerts the pilot that a stall is imminent. Spin A worse version of a stall is called spin, in which the plane spirals down. A stall can develop into a spin through the exertion of a sidewise moment. Depending on the plane, (and where its CG is located) it may be more difficult or impossible to recover from a spin. Recovery requires good efficiency from the tail surfaces of the plane; typically recovery involves the use of the rudder to stop the spinning motion, in addition to the elevator to break the stall. However the wings might block the airflow to the tail. If the centre of gravity of the plane is too far back, it tends to make recovery much more difficult. Another circumstance that may cause loss of control is when a hinged control surface starts to flutter. Such flutter is harmless if it just vibrates slightly at certain airspeed (possibly giving a kind of buzzing sound), but ceases as soon as the airspeed drops. In some cases however, the flutter increases rapidly so that the model is no longer controllable. The pilot may not be aware of the cause and suspect radio interference instead. To reduce the flutter, the control linkages should not be loosely fitted and the push rods should be stiff. Long unbraced push rods can create flutter as vibration whips them around. In some difficult cases the control surface has to be balanced, so that its centre of mass (gravity) is ahead of the hinge line. It should be located at about 60-65% of the length of the control surface from its inner end:

<< Previous Page |